In the rapidly evolving landscape of Information and Communication Technology (ICT), staying attuned to the latest MPTL testing methodologies is paramount. An essential component of this is Modular Plug Terminated Links (MPTLs) – a critical element in network infrastructures. When confronted with the task of certifying these links to either TIA or ISO standards, precision and adherence to proper procedures are non-negotiable.

The Quest for Accurate MPTL Certification

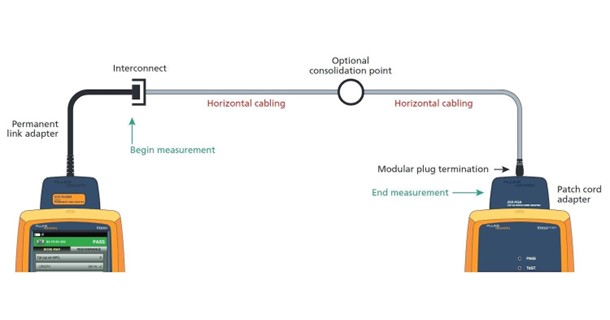

Picture this: You’re handed a project specification that mandates certification of all links, including MPTLs, to meet TIA or ISO standards. This necessitates the presence of “MPTL” in the resulting test reports, a requirement stipulated by clients and manufacturers alike. Generating a LinkWare™ report marked with “MPTL” hinges upon conducting tests using a DSX CableAnalyzer™ Series tester. This entails using a Permanent Link Adapter (PLA) on one end and a Patch Cord Adapter (PCA) on the other. Why this specific configuration? In a nutshell, it’s in accordance with industry standards.

Understanding MPTL’s Significance

Over five years ago, the TIA 568 cabling standards formally recognized MPTLs as a viable option for connecting devices when deploying an outlet or equipment cord is unfeasible or unsafe. This recognition is enshrined in the ANSI-TIA 568.2-D and also outlined in the ISO/IEC Technical Report 11801-9910. MPTLs have since gained prominence, serving as the go-to solution for linking PoE lights, surveillance cameras, Wi-Fi access points, and more.

The Roots of MPTL Testing Evolution

Before MPTLs found their way into industry standards, installers were already terminating horizontal cables to RJ-45 plugs and connecting them directly to devices. However, the term “MPTL” hadn’t been coined yet. The concept was documented in the BICSI 005-2016 Electronic Safety and Security standard as a modified single-connector permanent link. As time progressed, more than just nomenclature transformed; industry standards evolved, introducing a more robust approach to MPTL testing.

The Pitfall of Channel Adapter Testing for MPTLs

When the notion of terminating horizontal cables to plugs for direct device connection emerged, BICSI recommended a testing approach involving a modified single-connector permanent link method. This entailed attaching the main testing unit to a PLA at the near end and a remote unit with a channel adapter at the far end.

However, testing a link terminated to an RJ-45 via this method disregards the mated connection at the far end, rendering it an unreliable and incomplete evaluation. Optimistic results with excessive headroom could overlook poor termination practices of the far-end plug connection, ultimately jeopardizing proper functionality upon device connection.

The New Frontier of Accurate MPTL Testing

Recognizing MPTLs in industry standards ushered in the need for a more precise testing method. To incorporate the final plug connection in tests, TIA 568.2-D standards recommend using a PCA at the far end, in contrast to a channel adapter. This recommendation is mirrored in ISO/IEC TR 11801-9910, underscoring the importance of comprehensive testing.

Is PCA Utilization Truly Mandatory?

In unequivocal terms, yes, the standards necessitate the use of a PCA.

While PCAs are conventionally reserved for patch cord testing, and not all installers regularly employ them, some manufacturers still accept the older approach of using a PLA at the near end and a channel adapter at the far end for MPTL testing. However, to include device connections in this alternative method, manufacturers often require a specific field-terminated plug test cord, comprising a modular plug on one end and a jack on the other. This solution, unfortunately, has been flagged by standards committees for potentially yielding optimistic results.

Unwavering Adherence to Standards Irrespective of manufacturer allowances, industry standards unequivocally mandate PCA use for MPTL testing. Fluke Networks has strict adherence to these standards. Thus, any test conducted without a PCA cannot be reported as an “MPTL.”

For those who don’t frequently test patch cords and lack a PCA, they’ve made it more accessible by offering single PCA units in addition to pairs. Ensuring accuracy mandates matching the adapter category/class with the link under scrutiny (e.g., Category 6A / Class Ea). To further enhance testing precision, the DSX Series Certification testers now encompass MPTL test parameters.

12 Steps to Proper MPTL Testing

- Understand the Importance of MPTL Testing: Recognize the significance of Modular Plug Terminated Links (MPTLs) in modern network infrastructures and the need to certify them to industry standards.

- Acquire Proper Equipment: Obtain a DSX CableAnalyzer™ Series tester, a versatile tool designed for accurate testing of MPTLs.

- Choose the Right Adapters: Select a Permanent Link Adapter (PLA) to be connected to one end of the link and a Patch Cord Adapter (PCA) for the other end. This adapter combination aligns with industry standards for MPTL testing.

- Prepare the Testing Setup: Set up the testing environment with the PLA attached to the main testing unit and the PCA connected to the remote unit.

- Execute the Testing Procedure: Initiate the testing process using the DSX CableAnalyzer™ Series tester with the configured PLA and PCA adapters. This test configuration ensures compliance with accurate testing methods.

- Follow Standard Guidelines: Adhere to the guidelines outlined in TIA 568.2-D and ISO/IEC TR 11801-9910 standards, which recommend using a PCA at the far end rather than a channel adapter for comprehensive MPTL testing.

- Ensure Adapter Compatibility: Verify that the adapter used matches the category/class of the link being tested, such as Category 6A / Class Ea, to ensure accurate measurements.

- Interpret Test Results: Analyze the test results generated by the DSX CableAnalyzer™ Series tester, looking for the “MPTL” label on the LinkWare™ report. This indicates successful certification of the MPTL according to industry standards.

- Invest in PCA: If MPTL testing is a routine task, consider investing in Patch Cord Adapters (PCAs) for accurate and reliable testing. Single PCAs are now available alongside paired options for convenience.

- Comply with Standards: Maintain unwavering adherence to industry standards by conducting MPTL tests exclusively with a PCA on the far end. This approach ensures consistent and trustworthy results.

- Enhance Testing Precision: Make use of the MPTL test limits integrated into the DSX Series Certification testers to further enhance testing precision.

- Advocate for Accuracy: Recognize the value of accurate MPTL testing in ensuring robust network performance and preventing potential issues down the line.

By following these steps, ICT professionals can confidently and effectively test Modular Plug Terminated Links (MPTLs), contributing to the reliability and quality of network connections in today’s dynamic technological landscape.

For professionals engaged in regular MPTL testing, a PCA investment is invaluable. It mitigates the risk of non-functioning links upon device connection and prevents test results rejection by clients. In the dynamic ICT landscape, precision in MPTL testing is the linchpin for robust network infrastructures.

For more information, please reach out to a C&C representative by clicking here.

Last Updated on September 7, 2023 by Josh Mahan