Understanding the differences between Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) is crucial for businesses navigating the realm of product development and manufacturing. Both terms refer to established methods of production but cover distinct aspects of the manufacturing process. OEM refers to the production of components or products that are designed and specified by the company that will eventually sell the finished product to end consumers. Contrarily, ODM services involve the complete design and production of the product by the manufacturer, which is then branded and sold by the company.

Selecting between OEM and ODM manufacturing highly depends on the company’s capabilities, resources, and strategic business goals. With OEM, a company may have greater control over the design and quality of the product, as it is typically responsible for the product’s design and specifications. This choice can be preferable for businesses aiming to establish a unique brand identity or those with innovative product designs. On the other hand, ODM allows companies to leverage the design expertise and efficient production processes of manufacturers, which can be advantageous for businesses looking to reduce costs, save time, or lack in-house design capabilities.

Key Takeaways

- OEM manufacturing allows companies to control product design and specifications, suiting unique brand identities.

- ODM manufacturing is a design-to-production service by the manufacturer, often reducing costs and time-to-market for companies.

- Selecting between OEM and ODM depends on factors such as design capability, resource availability, and business strategy.

Defining OEM and ODM

In the manufacturing industry, understanding the roles of Original Equipment Manufacturers (OEM) and Original Design Manufacturers (ODM) is crucial for businesses seeking to produce and market products.

What is an OEM?

An OEM refers to a company that manufactures parts or products that are then sold under another company’s brand. It operates under the specifications provided by the brand owner, focusing on production and ensuring that the components or products meet the required quality and performance standards. Its involvement is typically limited to manufacturing, with the design and development being handled by the brand that will ultimately sell the finished product.

What is an ODM?

An ODM, on the other hand, provides comprehensive services from design to production. This type of manufacturer designs products, oftentimes customizable, which are then branded and sold by various companies. This approach allows businesses to leverage the ODM’s expertise in both design and manufacturing to bring products to market more quickly. An ODM can be especially beneficial for companies lacking in design capabilities or looking to expand their product lines with minimal investment in new product development.

Key Differences Between OEM and ODM

When navigating the terrain of manufacturing models, understanding the specifics of OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) is crucial for businesses looking to forge a clear path to market success.

Design and Intellectual Property

OEM: An OEM is traditionally responsible for manufacturing products based on the design and intellectual property provided by another company. The client retains all design rights, with the OEM simply acting as a production facility for the client’s specifications.

ODM: Conversely, an ODM handles both the design and manufacturing aspects of product development. Here, the ODM not only manufactures the products but also creates the designs themselves, often retaining the intellectual property rights unless agreed otherwise.

Manufacturing and Production

OEM: This model is focused solely on manufacturing and production. An OEM produces components or products under the branding of another company, ensuring that the client’s quality specifications are strictly met.

ODM: An ODM’s role extends beyond production to include designing the product, thereby streamlining the process from conception to market. They offer a complete package of design, manufacturing, and sometimes even product testing.

Quality and Branding

OEM: Quality control is a shared responsibility between the OEM and the client company. An OEM must replicate quality as per the client’s requirements while the branding is wholly owned by the client, reflecting its image and reputation.

ODM: Quality benchmarks are set by the ODM according to industry standards and customer expectations. In the case of ODMs, the branding might be that of the ODM if a product is sold directly to consumers, or it could bear the branding of a purchasing company under a private label agreement.

Advantages and Challenges of OEM

Original Equipment Manufacturing (OEM) allows a company to produce items according to its exact specifications, ensuring consistent product quality and alignment with the brand’s identity. However, this approach can require significant investment in design and manufacturing processes.

Quality Control

With OEM partnerships, a company exercises direct oversight over the production processes, which can lead to higher quality products. It retains the ability to enforce its own quality control standards, potentially reducing the incidence of defects and maintaining brand reputation.

Brand Identity

An OEM strategy ensures that products stay true to the company’s established brand identity. Manufacturing products to precise specifications supports a cohesive brand experience, reinforcing customer recognition and loyalty.

Customization Options

Customization is a key benefit of OEM; companies can design their products to meet specific market needs or create unique features that differentiate them from competitors. This level of customization helps in targeting niche markets with specialized requirements.

Investment Requirements

The main challenge in an OEM model is the investment requirement. Companies must invest in research and development, design, and tooling to produce unique products. This is a substantial upfront cost, which may pose a barrier to entry for smaller businesses or startups.

Advantages and Challenges of ODM

Original Design Manufacturing (ODM) is a business model where manufacturers design and produce products that are eventually rebranded and sold by other companies. This approach to manufacturing presents businesses with both advantages and challenges in terms of cost, development, and intellectual property.

Cost Efficiency

Advantages: ODM offers a cost-effective solution for businesses looking to launch products without incurring high upfront design and tooling expenses. Since the ODM manufacturer spreads out the cost of product design and development across multiple clients ordering the same base product, individual companies benefit from reduced costs.

Challenges: Businesses may have to compromise on product uniqueness, as they share similar product designs with others in the market. This limitation can potentially affect long-term brand value and pricing power.

Reduced Development Time

Advantages: By adopting ODM, companies can market their products more quickly. The manufacturer usually has pre-designed and tested products, which significantly cuts down the product development lead time. This rapid go-to-market strategy can be crucial in industries where time is of the essence.

Challenges: Companies face the challenge of being less involved in the creation process, thus having limited influence on the product’s final features, specifications, and quality checkpoints. This reliance on the ODM’s expertise and processes can lead to concerns over product quality and performance.

Limited Brand Differentiation

Advantages: ODMs facilitate businesses in entering markets with products that are already established and accepted by consumers. This reduces the risks associated with market introduction and consumer acceptance.

Challenges: Companies often struggle with differentiation since ODM products are not exclusive and can be procured by competitors as well. Hence, there is a heavy reliance on brand strategy and marketing to distinguish their offerings.

IP Rights and Patents

Advantages: By engaging with ODMs, companies need not navigate the complex patent acquisition process or deal with R&D intricacies related to new product development.

Challenges: Intellectual property rights can become an issue for businesses as they do not own the design of the product. This can lead to potential legal complications or restrictions on the modification and customization of products. Moreover, businesses must carefully negotiate with ODMs to protect their interests and avoid patent infringement issues.

Considerations for Selecting OEM or ODM

When venturing into manufacturing, it’s critical for a business to align its strategic decisions with its core objectives. In selecting between OEM and ODM, one must evaluate their business model, market position, financial constraints, and technical requirements.

Business Model and Goals

A company’s business model is paramount when choosing between Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM). For those focused on brand distinction and research and development, OEM provides an avenue to design unique products that reflect the brand identity. OEM partners fabricate products based on the company’s exact specifications, enabling full control over the end product.

- Brand Name: Strengthening the brand through unique designs.

- Research and Development: Ensuring the product aligns with company innovation.

Market Research and Competitors

Understanding the market is essential. Through comprehensive market research, a company can discern whether pursuing OEM or ODM is more beneficial in terms of standing out among competitors and meeting consumer demands. If competitor analysis reveals a market saturated with generic products, ODM could be a swift route to market. Conversely, to differentiate, OEM might be the better strategy.

- Marketing: Aligning product development with market needs.

Budget and Volume

Budgeting decisions influence the choice between OEM and ODM. OEM typically requires more significant investment due to custom design and development costs. In contrast, ODM can offer a more cost-effective solution with lower minimum order quantities. Companies must weigh their budget constraints against the expected production volume to determine the best financial fit.

- Budget: Determining which model aligns with financial capabilities.

- Volume: Assessing the business’s ability to meet minimum order requirements.

Product Complexity and Expertise

The complexity of the intended product and the company’s internal expertise are decisive factors. Companies with intricate product designs that require specialized know-how might lean towards OEM for its capability to produce complex goods. In contrast, businesses lacking in-house design skills may find ODM to be a valuable alternative, allowing them to leverage the manufacturer’s existing designs and expertise.

- Product Complexity: Determining if proprietary design is necessary.

- Expertise: Utilizing the manufacturer’s skills to compensate for in-house gaps.

Each of the above considerations plays a critical role in determining whether an OEM or ODM manufacturing model will best serve a business’s interests, aligning with their overall strategic plan.

The Role of Contract Manufacturers (CMs)

Contract Manufacturers (CMs) serve as the essential backbone for companies looking to outsource their product manufacturing. They provide comprehensive solutions that range from production to customer service, accommodating both OEM and ODM project demands.

OEM and ODM Services by CMs

Contract Manufacturers offer services for Original Equipment Manufacturing (OEM) where they produce products based on the client’s specific design and requirements. Similarly, for Original Design Manufacturing (ODM), CMs may take a more active role in designing products based loosely on the client’s idea, utilizing their existing product designs and expertise.

- OEM services: Precise execution of client’s designs

- ODM services: Adaptation and innovation on existing designs

Selecting a Contract Manufacturer

When selecting a Contract Manufacturer, companies consider several factors to ensure alignment with their project needs. They assess the CM’s:

- Capabilities: Can they meet the technical requirements?

- Quality: Do they adhere to standards and maintain consistency?

- Communication: Is there a clear and reliable line of dialogue?

Communication stands out as a vital aspect of this relationship, as it underpins the ease of negotiation and the effectiveness of customer service provided.

Negotiating Terms with CMs

The negotiation process with CMs is critical and requires clear terms that cover:

- Production costs: Establishing a fair price for services rendered.

- Timelines: Agreeing on realistic production schedules.

- Intellectual property: Ensuring protection of designs and patents.

- Quality control: Addressing compliance with standards and accountability.

Successful negotiations hinge on both parties’ understanding of expectations and deliverables, ensuring a partnership that benefits all involved, including the ultimate suppliers in the value chain.

Industry Examples and Case Studies

In analyzing OEM and ODM models, specific industry examples provide insights into these practices. The section below showcases case studies demonstrating how the choice between OEM and ODM can impact production, partnerships, and product development across various markets.

Electronics and Consumer Goods

Apple Inc. is a prime example of an OEM strategy, where they design their products and outsource manufacturing to suppliers like Foxconn. This approach allows Apple to maintain strict control over the design and quality of their electronics, from iPhones to MacBooks, while leveraging the assembly efficiency of established manufacturers.

- Samsung, in contrast, employs a blend of OEM and ODM, depending on the product line. For their consumer electronics segment, they often favor OEM, ensuring brand consistency and technology leadership.

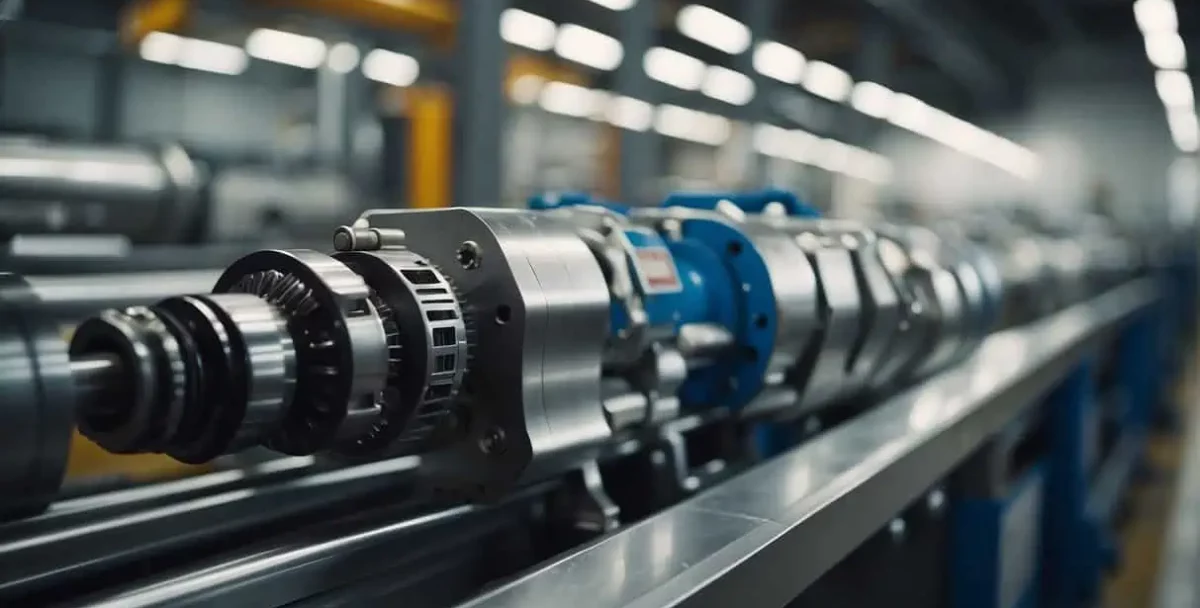

Automotive and Industrial Products

The automotive industry relies heavily on OEM for parts production. Car manufacturers like General Motors or Toyota provide specifications for components that specialized suppliers then produce. This sector highlights an OEM focus on component quality and brand integrity.

- Efficiency gains are often realized through long-term partnerships with trusted suppliers, enabling a streamlined production process.

Healthcare and Medical Devices

In the healthcare sector, companies often opt for OEM when it comes to specialized equipment. This ensures that devices like MRI machines and pacemakers meet stringent regulatory standards and incorporate the latest technological advancements.

- For more generic products, medical companies may choose the ODM route, as it can reduce costs while still adhering to required healthcare regulations. ODM allows these companies to market products faster by reducing the development time.

Global Sourcing and Manufacturing

Global Sourcing and Manufacturing entail a complex interplay between supply chain management, compliance with international standards, and efficient logistics. As businesses expand their reach, understanding these facets becomes crucial for operational excellence and competitive advantage.

Supply Chain Management

In global sourcing, supply chain management is paramount, involving strategic procurement from international suppliers to ensure uninterrupted production. Companies must align their supply chain strategies with market demands and maintain inventory accuracy, while Global Sources and other trade platforms offer avenues for sourcing materials and finished goods.

International Trade and Logistics

Logistics plays a critical role in connecting sellers and buyers worldwide, providing a framework for the movement of goods. To optimize international trade, businesses must incorporate efficient shipping solutions and understand ecommerce dynamics, which can strengthen their global footprint. The effectiveness of shipping and logistics directly impacts the cost, speed, and reliability of supply chains.

Compliance and Quality Standards

Adherence to compliance and quality standards is non-negotiable in the global market. Companies must ensure that products meet quality control benchmarks and that inspection protocols are thoroughly implemented. It is critical to integrate comprehensive inspection measures to mitigate the risk of non-compliance, which can lead to heavy penalties and erosion of brand credibility.

Tools and Resources

Selecting the right tools and resources is essential for differentiating between OEM and ODM manufacturing and for effectively managing the production process. Manufacturers and businesses should leverage a mix of trade shows, B2B platforms, and prototyping services alongside comprehensive project management and communication tools to navigate the complexities of bringing a product to market.

Trade Shows and B2B Platforms

Trade Shows such as the Canton Fair offer invaluable opportunities for businesses to explore OEM and ODM capabilities firsthand. Exhibitors can showcase their manufacturing prowess, while attendees can network and forge new partnerships.

B2B Platforms, on the other hand, provide a digital space for manufacturers and businesses to connect. These platforms facilitate the exchange of services and products, and simplify the process of finding the right OEM or ODM partner. Examples include Alibaba and ThomasNet.

Prototyping and Sample Testing

Developing a prototype is a critical step in both OEM and ODM manufacturing. It helps in visualizing the final product and in making necessary adjustments before mass production. Sample testing, moreover, ensures the product meets the required standards and specifications. For OEM, where specs are provided by the client, this stage is vital to meet their precise requirements.

Project Management and Communication Tools

Efficient project management is pivotal for coordinating between different stakeholders in the manufacturing process. Tools such as Asana, Trello, or Jira can track progress and keep schedules on target.

Effective communication underpins the success of OEM and ODM projects, ensuring clarity and prompt resolution of issues. Slack, Microsoft Teams, and email are standard tools that keep teams connected and informed throughout the lifecycle of a manufacturing project.

Frequently Asked Questions

This section provides concise answers to common inquiries about OEM and ODM manufacturing, delineating the nuances of each to assist businesses in making informed decisions.

What are the key differences between OEM and ODM in terms of manufacturing processes?

Original Equipment Manufacturer (OEM) involves producing parts or products based on the designs provided by another company. Original Design Manufacturer (ODM), on the other hand, provides both the design and production services, offering a more comprehensive solution where clients receive finished products under their brand name.

Can you list some advantages and disadvantages of choosing OEM over ODM for product development?

Advantages of choosing OEM include greater control over product design and quality, maintaining proprietary design secrecy, and a stronger alignment with the company’s unique specifications. Disadvantages can be the higher cost associated with custom design and longer time to market due to development processes. Conversely, ODM can be more cost-effective and provide faster market entry.

How do businesses decide whether to partner with an OEM or an ODM for their product needs?

Businesses often choose between OEM and ODM based on their capabilities in design and development, budget constraints, time-to-market goals, and the desired level of control over the manufacturing process. Companies may opt for an OEM if they have the expertise to design in-house, or an ODM when they seek a turnkey solution.

What distinguishes an Original Brand Manufacturer (OBM) from OEM and ODM?

An Original Brand Manufacturer (OBM) creates, manufactures, and sells products under its own brand. Unlike OEM and ODM, OBMs invest in brand development and consumer marketing, and they retain intellectual property rights for their products.

How does the role of a Contract Manufacturer (CM) differ from that of an OEM or ODM?

A Contract Manufacturer (CM) is a company hired to produce goods for another company on a contract basis. CMs may not offer design services, differing from ODMs, and unlike OEMs, they usually take on the full production responsibility for a client’s existing designs.

Are there notable examples of companies that serve as OEMs or ODMs in the technology sector?

In the technology sector, Foxconn is a prominent example of an OEM, known for manufacturing parts for major brands. Quanta Computer is an example of an ODM, designing and manufacturing laptops for various global brands. These companies have specialized roles in the tech industry’s supply chain.

Last Updated on February 12, 2024 by Josh Mahan