Power and Voltage Ratings for Connectors

Connect the dots! The power connector industry was worth more than $2 billion in 2020 and will reach more than $2.8 billion in value by the end of 2027. While the large industry gives you ample opportunities to find the connectors you need, the sheer number of options can be overwhelming.

Examining power and voltage ratings for connectors is the greatest way to narrow down your options. So what are these ratings, and what should you look for in an electrical connector? Here are the essentials you must know about electrical connectors and the connector power loss rating today.

Formulas for Power and Voltage Ratings

You must distinguish current, power, and voltage from one another. Many people know the formula for calculating power: power (watts) = voltage (volts) x current (amps).

However, putting in the values for your electrical system or power distribution unit can produce an unusually high number of watts. Voltage is the measure of the electromotive force which allows electricity to flow. A connector’s purpose is not to lose voltage but to allow electricity to flow. Therefore, you want a formula that will determine the dissipated power as the electrons in your system flow and takes the resistance of your connector into account.

Here is your ideal formula: power (watts) = current (amps) squared x resistance (ohms). It meets both criteria, informing you of the energy lost as the electrons flow through the connector and factoring in the resistance of the connector. So, when buying a connector, find one that can handle a high amount of current while providing as little resistance as possible.

You may hear or read the term “high-power connector.” There is no universal definition of a high-power connector, so do not prioritize a product that claims to be one over another. You need to see what the power and voltage ratings are to determine the most suitable connector.

Related: Understanding True, Reactive, and Apparent Power

Maximum and Working Voltage Ratings

The electromotive force can be powerful enough to push electrons out of one conductor and into another. Most connectors will attract these pushed electrons, creating a flashover or arc flash that can damage your system or spark a fire.

The maximum voltage rating for a connector will tell you how much voltage it can handle so you can prevent flashovers. The maximum rating does not mean that you should operate your system at that high of a voltage continuously.

The working voltage rating is a recommendation for the voltage of your system. The rating depends on the connector you are using; some companies recommend their connectors operate at one-third of the maximum rating, while others recommend half the maximum voltage. Do not set your system at the working voltage and leave it. You need to check how stable your power source is so you don’t experience a fluctuation that can create a flashover.

Want to plan your data center with safe and effective connectors? Hire the data center planners at C&C Technology Group today!

Types of Connectors

There are three main types of electrical connectors. To find the right power and voltage ratings for your needs, you should understand what each type of connector is like.

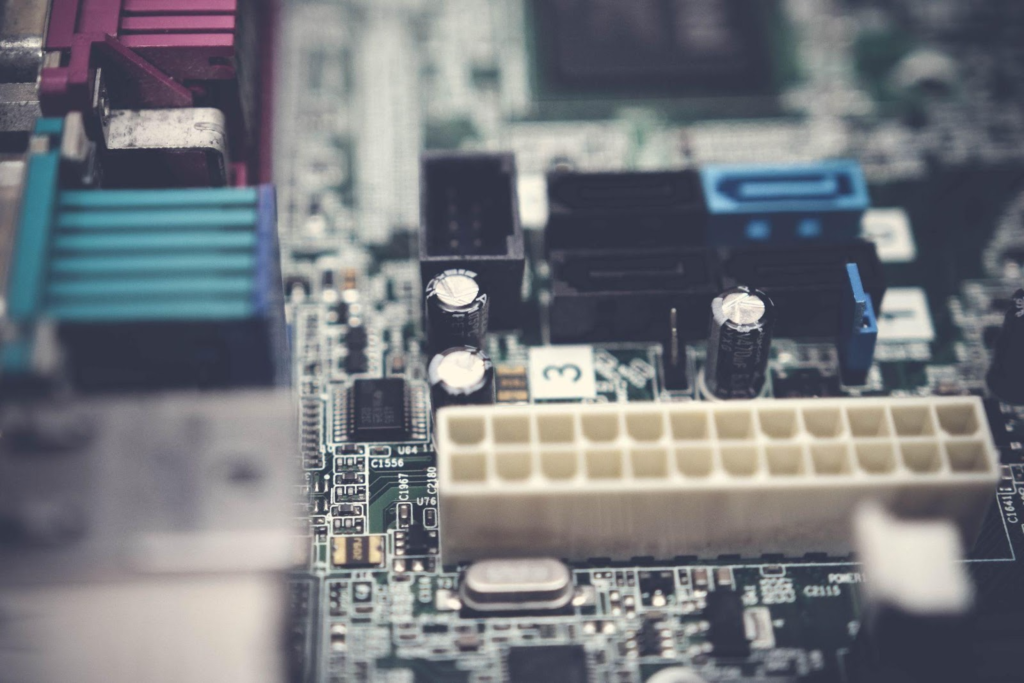

Board-to-Board Connectors

Board-to-board (BTB) connectors connect two printed circuit boards together. Most companies market BTB connectors based on their voltage per pin. Most BTB connectors can handle a few amps, provided you are at a typical voltage level. If you need a higher voltage level, you need to find a different BTB.

There are several types of BTB connectors. Fully-shrouded or coaxial connectors can handle high-power applications and high currents. You can purchase pin header blocks if you’re not worried about high currents. Look at your power distribution unit before determining what type of BTB you should buy. Any connector you buy should fit seamlessly into your unit.

Related: How Do Power Distribution Units (PDUs) Work?

Wire-to-Wire Connectors

Wire-to-wire connectors (also called cable-to-cable connectors) connect two wires together. One wire is permanently attached to one end of the connector, while the other end serves as a separate interface.

Wire gauge is a significant determinant of current; the thicker a wire is, the more current travels through the wire. This means that you need to select a wire-to-wire connector with very high maximum and working voltages if you have thick wires.

Wire-to-Board Connectors

Wire-to-board connectors connect a PCB to a wire. They operate similarly to wire-to-wire connectors, though you can find wire-to-board connectors that run at low voltages. They can work for any application, including low-voltage differential signaling, making them ideal for communications systems and software companies.

Do you need help figuring out what connectors are suitable for you? Call the experts at C&C Technology Group now to narrow your options down!

Other Factors of Connectors

The material of your connector has a significant impact on power and voltage. Copper has an electrical conductivity of 58.5 Siemens per meter, so find a connector with a copper contact pin. Some pins have tin plates on them, but tin can wear down, especially if you disconnect your connector regularly. Try finding a sturdier material if your connector will be in a high-vibration area.

The interior of your connector should have conducting materials, but the housing should have insulation and arc resistance. Look for a product with nylon or polymer.

The size of your connector does not mean that your connector has a higher maximum voltage level. Many companies are designing their connectors to be small so they can fit into any electrical system. Do not buy a connector just because it is big or can connect to several circuits at once, especially if it has a low voltage rating.

If your connector disconnects, your circuit may shut down. If your circuit is in a high-vibration environment, buy a connector with a locking mechanism so it will stay in place. The mating cycle is the number of times your connector can be removed from your system before its performance is affected. Once your connector exceeds its mating cycle, its maximum and working voltage ratings will drop. You need to adjust the amount of electricity flowing through your circuit and buy a new connector soon.

Related: Data Center Power Design

Last Updated on June 8, 2023 by Josh Mahan