Navigating the world of Printed Circuit Board (PCB) assembly can be complex, especially when understanding the nuances of different mounting technologies.

Two key players in this field are Through-Hole Technology (THT) and Surface-Mounted Devices (SMD). Each brings unique strengths, shaping how we design and implement electronic components.

This article aims to demystify these technologies, comprehensively comparing THT and SMD.

Whether you’re a seasoned professional or a curious novice, join us as we delve into the intricate world of PCB assembly, unraveling the differences between THT and SMD.

Related: Why Build A Digital Building?

Through Hole Technology (THT) – A Time-Tested Approach

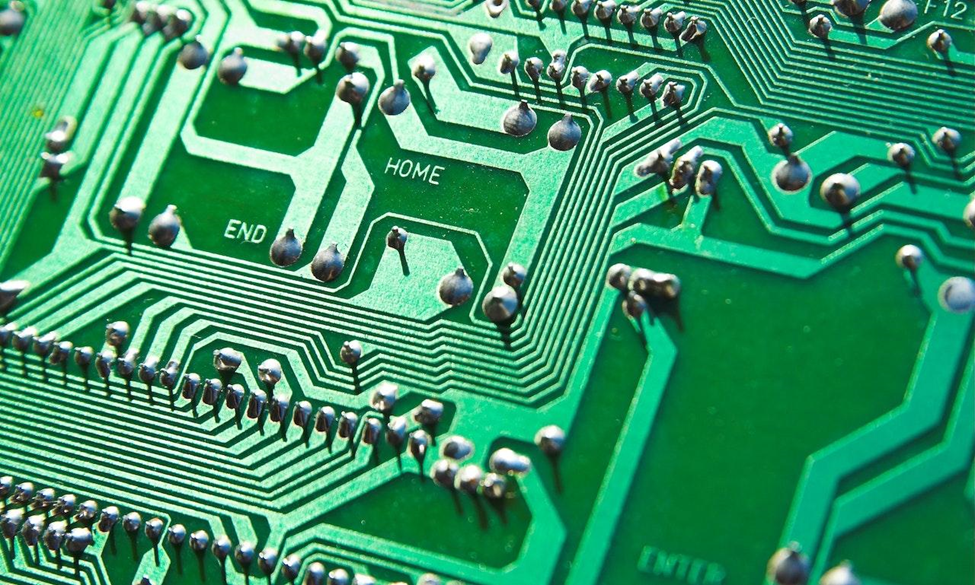

Through-Hole Technology (THT) has long been a cornerstone in Printed Circuit Board (PCB) construction. THT’s traditional dominance, rooted in the early days of electronics, stems from its robust and reliable methodology.

The Process

It’s a process that involves drilling holes into the PCB, inserting components with leads into these holes, and then soldering them to create strong mechanical bonds. This technique ensures a high level of reliability, with fewer variables causing solder issues compared to other methods.

Recent Developments

In recent years, advancements in THT have led to the development of plated through holes. This innovation allows a mix of through-hole and surface mount components to be soldered in a single process, further enhancing the versatility of THT.

Advantages

The advantages of THT are numerous. Its strong mechanical bonds make it suitable for components that must withstand physical stress or environmental conditions. The reliability of THT is renowned, making it a preferred choice for applications where failure is not an option.

Disadvantages

However, THT is not without its challenges. The process can be more expensive due to the manual labor involved in drilling and placing components. Automation of component placement in THT is more complex and costly compared to Surface Mount Technology (SMT), making it less suitable for high-volume production.

Furthermore, the physical size of through-hole components can limit design flexibility and increase the overall footprint of the PCB. This issue can be a significant disadvantage in an era where miniaturization and compact design are highly valued.

In a world increasingly dominated by Surface Mount Devices, C&C Technology Group recognizes the enduring value of Through Hole Technology (THT).

By understanding the specific needs of each project, C&C ensures that THT is not just a component of the solution but a cornerstone, delivering durability and performance where it matters most.

Ready to harness the power of both THT and SMD for your next project? Connect with C&C Technology Group today and let our experts guide you to the perfect solution tailored to your needs.

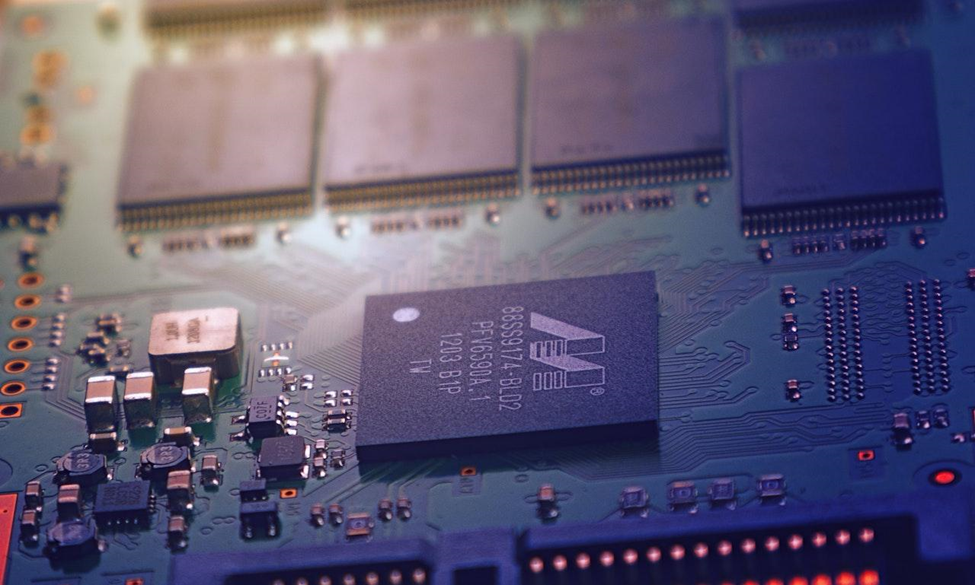

Surface Mount Devices (SMD) – The Future of Compact Design

Surface Mount Devices (SMD) are revolutionizing the PCB assembly landscape, heralding a new era of sleek, space-efficient designs.

As the cornerstone of modern electronics, SMDs offer unparalleled advantages in compactness and performance.

Key Highlights of SMD

- Space Efficiency: SMDs are designed to mount directly onto the PCB surface, eliminating the need for drilled holes, thus optimizing space and reducing overall device weight.

- Enhanced Performance: With minimized internal connections, SMDs can operate at higher frequencies and produce less noise, ensuring devices function at their peak.

- Versatility: SMDs come in various types, each catering to specific electronic needs.

- Resistors: Regulate current flow within circuits.

- Capacitors: Store and discharge energy as needed.

- Integrated Circuits: Serve as the operational core of many electronic devices.

- Precision in Placement: Integrating SMDs into PCBs demands advanced machinery and a high level of expertise, emphasizing the precision and skill inherent in the process.

- Broad Applications: From smartphones to medical devices, SMDs are integral to many modern electronics, showcasing their widespread relevance and appeal.

With their compact nature and enhanced performance capabilities, Surface Mount Devices undeniably shape the future of electronic design and assembly.

At C&C Technology Group, our commitment to innovation drives us to integrate SMDs seamlessly into our projects, ensuring our clients benefit from the latest PCB assembly advancements.

Related: What is Edge Computing?

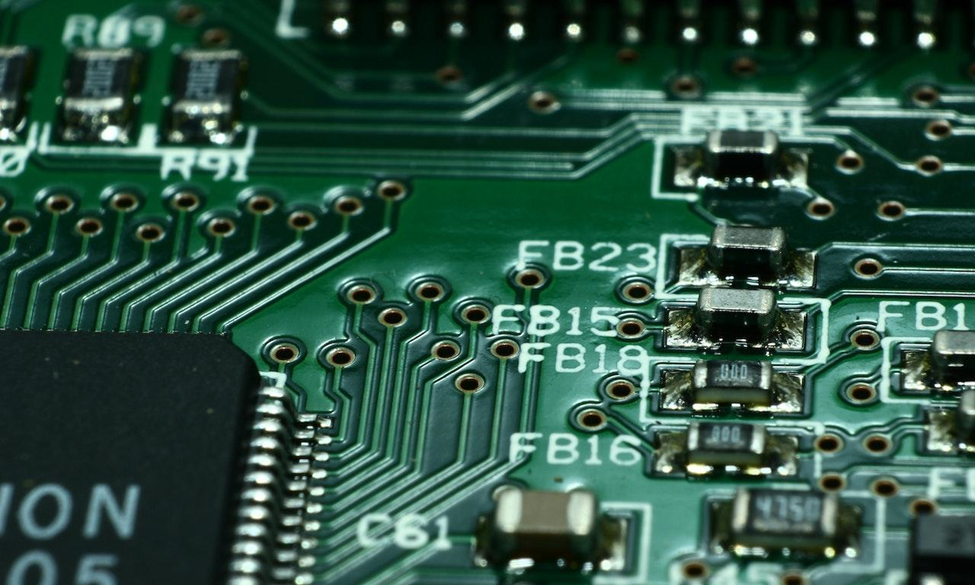

Comparing THT and SMD – A Tailored Solution

In the intricate world of PCB assembly, two dominant technologies emerge: Through Hole Technology (THT) and Surface Mount Devices (SMD).

Each offers unique advantages, and understanding their differences is crucial for tailored electronic solutions. Let’s look at some of the critical distinctions between these two technologies.

Mounting Technique

- THT: Involves drilling holes through the PCB, inserting component leads into these holes, and soldering them in place. This method provides strong mechanical bonds, ensuring durability.

- SMD: Components are directly mounted onto the PCB surface, leading to a more compact design and reduced weight.

Performance and Reliability

- THT: Known for its high reliability, especially in environments with mechanical stress. Fewer variables can cause soldering issues, making it a robust choice for specific applications.

- SMD: Offers enhanced performance due to shorter internal connections, allowing devices to operate at higher frequencies with reduced noise.

Cost Implications

- THT: While offering high reliability, THT can be more expensive due to manual labor and challenges in automating component placement.

- SMD: Generally less expensive in assembly but requires a higher initial capital investment for machinery and technology.

Applications and Versatility

- THT: Preferred for products that must withstand mechanical stress or require manual adjustments, such as audio equipment.

- SMD: Ideal for devices that prioritize sleekness, portability, and high-speed performance, like smartphones and modern computers.

At C&C Technology Group, we’ve witnessed the evolution and nuances of both Through Hole Technology (THT) and Surface Mount Devices (SMD) in electronics.

Each holds its unique advantages, and the specific demands of a project meticulously determine our choice between them.

Whether our clients prioritize durability, compactness, cost-efficiency, or performance, our deep understanding of the strengths and limitations of both THT and SMD allows us to craft solutions that perfectly align with their objectives.

Partner with C&C Technology Group for exceptional Manufacturers Rep Services. Reach out to us today!

Harnessing the Power of THT and SMD: C&C Technology Group’s Commitment to Excellence

In the dynamic world of electronics, C&C Technology Group stands at the forefront, expertly navigating the intricacies of both THT and SMD.

Our dedication to understanding and integrating these technologies ensures our clients receive solutions tailored to their unique needs. As we continue to innovate, our commitment remains unwavering: to deliver unparalleled quality and performance in every project.

Trust in C&C Technology Group to be your guide in the ever-evolving landscape of electronic design and assembly.

Related: What Do You Need in a Smart Office Space?

Last Updated on August 21, 2023 by Josh Mahan